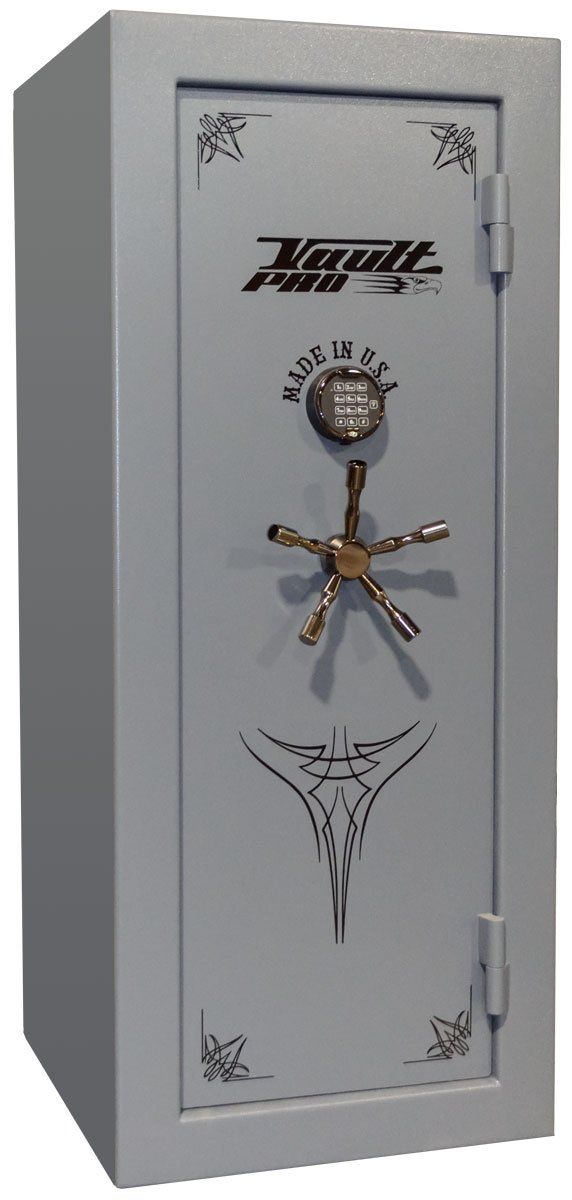

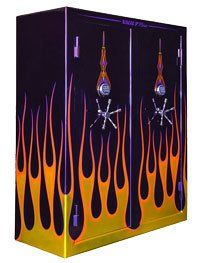

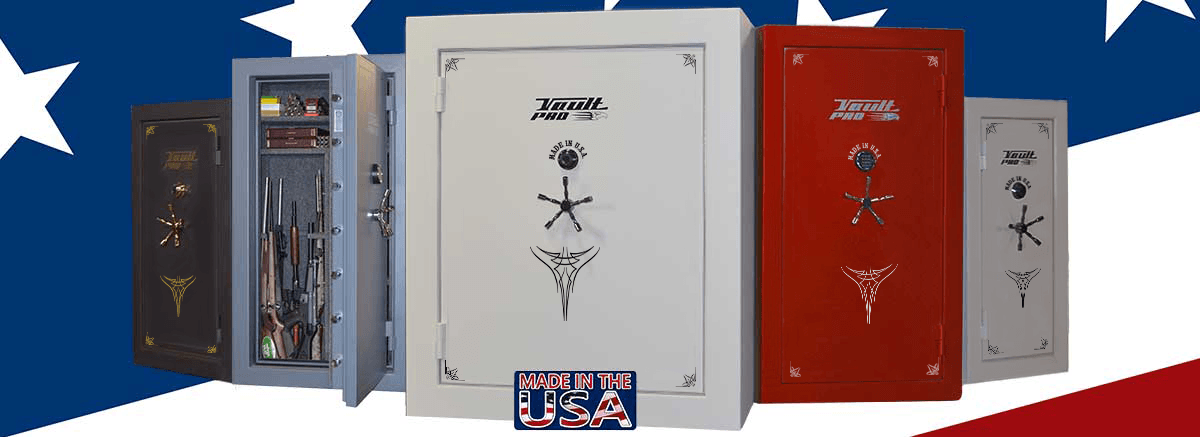

Our American made Eagle Series gun safes provide superior protection against break in and fire and come in three model series: Silver, Gold and American Eagle. All our gun safes are made with pride in the USA and come with a long list of standard features not found on other safes. We are Custom Safe Specialists. We can customize any of our Eagle Series Safes or create a safe to meet your specific requirements. Please review our information then call to talk with one of our Vault Pro's: CLICK TO CALL

How to Choose the Best Safe for You.

Looking for a new gun safe, home safe, or safe for your business? Purchasing the Proper Safe to Keep Your Guns Safe and Valuables Secure is one of the Most Important Decisions You Will Make. Below are a Some of the Top Questions You Should be Asking Before Buying a Safe.

- Is Fire Protection Your Priority in Choosing a Gun Safe?

- Are You Concerned About High Burglary Resistance When Selecting a Gun Safe?

- Are You Looking for a Safe with Both High Fire and Burglary Resistance?

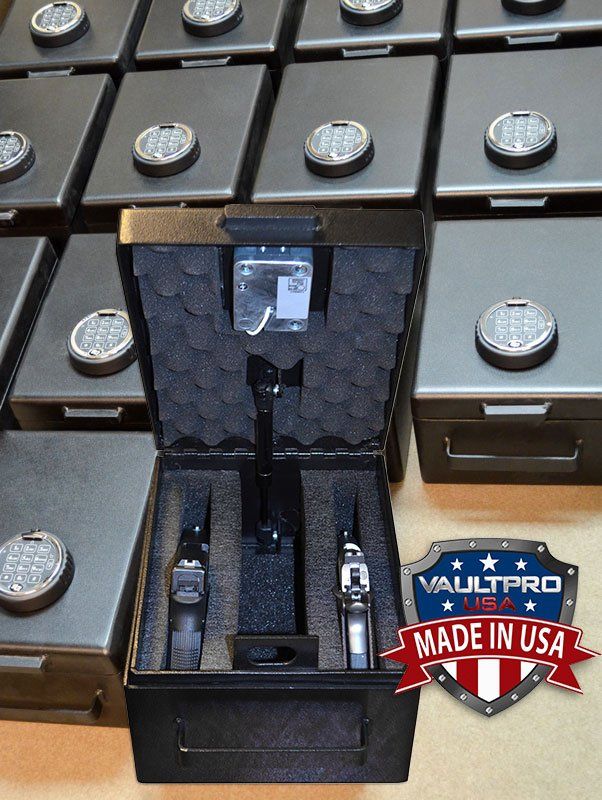

- How Many Weapons and What Type Will You be Securing?

- Do You Wish to Protect: Jewelry, Electronic Devices, Cash, Bullion, Precious Metals or Important Documents from Both Theft and Fire?

SAFE SELECTOR - CHOOSE SAFES by SIZE and CAPACITY

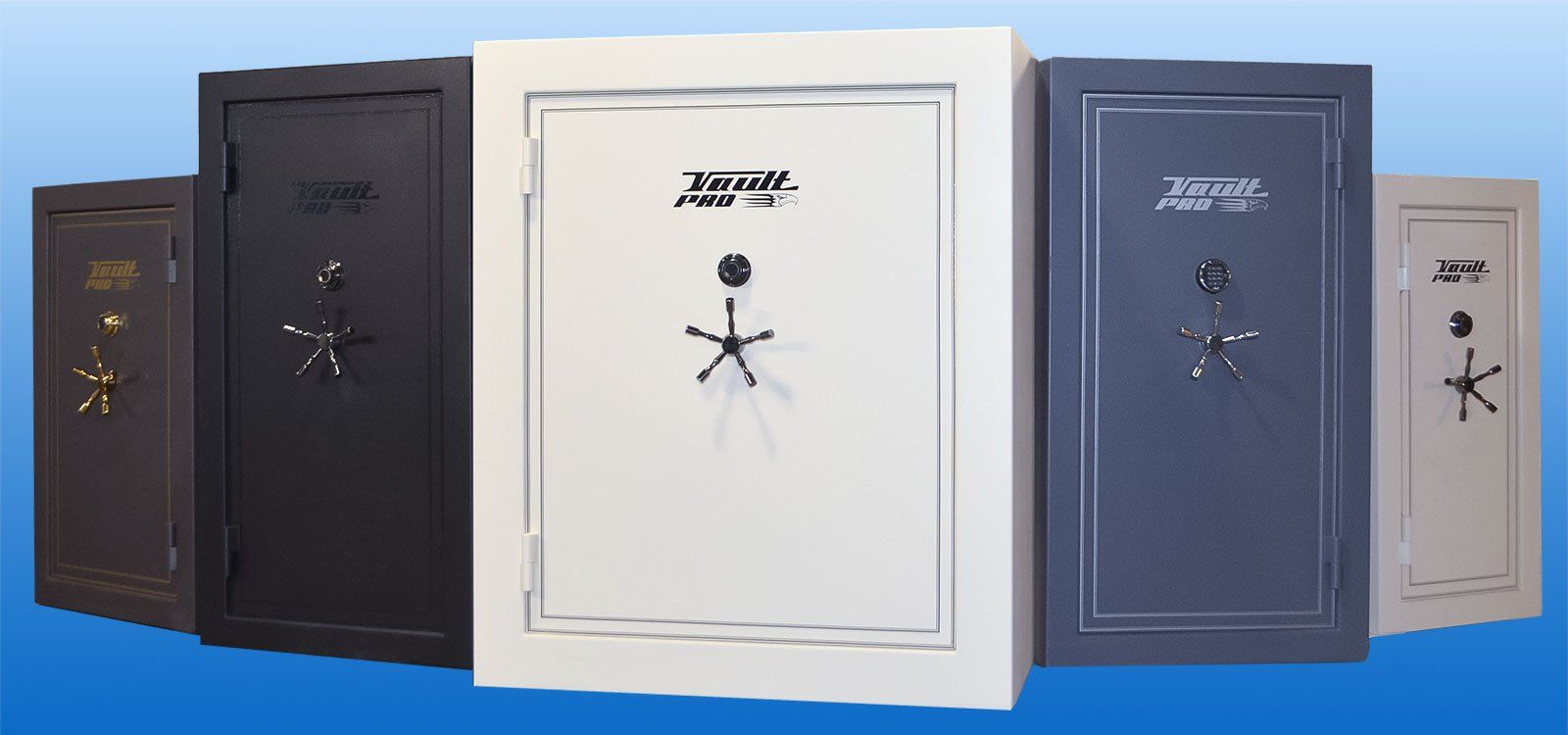

Eagle Series Safes - Three Series - Seven Models - 25 to 60 Long Gun Capacities - Made in USA!

Eagle Series Safes. Superior Safe Design and Build Quality. Hand Crafted with Pride in the USA. The Best Safes for Home, Office, Institutional or Government Secure Storage.

SAFE SELECTOR - CHOOSE SAFES by SIZE and CAPACITY

We Manufacture and Sell Only High Quality American Made Safes

NOT

Cheap Low Quality Foreign Made Safes as Others do. All Our Safes, Vault Doors and Modular Shelters are Made in the USA. Don't be fooled by other so-called safe companies that try and sell their cheap foreign made safes as American. Ask them! Do you Make Your Safes in the USA? We invite you to our American factory to see how we build all our security products.

STEEL = SECURITY

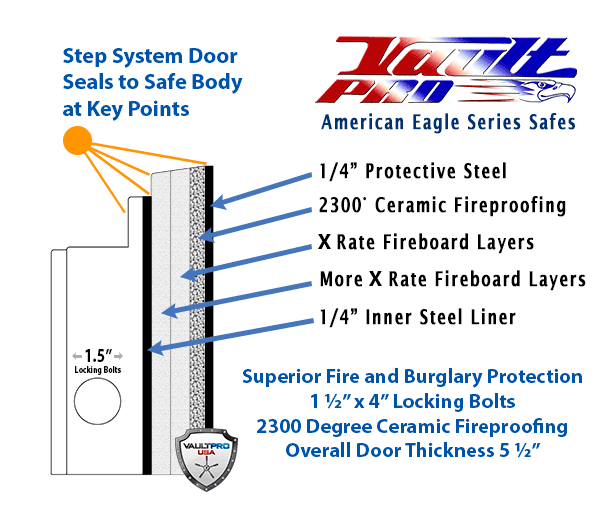

Most Vault Pro safes are built using one piece of steel bent from the left side of the body around the back to the right side. We can then square, fit and weld the top and bottom of the body with full length welds both inside and out.

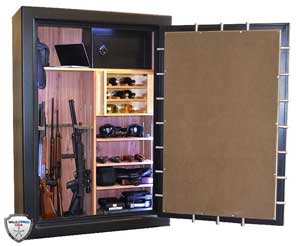

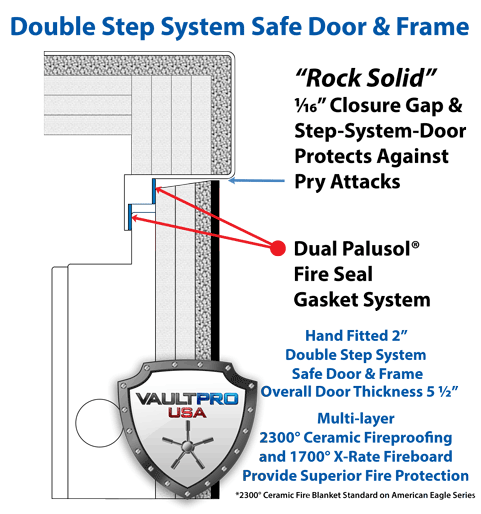

Once the safe bodies are fire insulated, the step system frame is built, and shelving tracks are added. Each body gets a hand cut and custom fitted step system door that is mated precisely to the body with a tolerance of no more than 1/16". The door is then built and hinged with very heavy-duty hinges.